|

| July 19, 2016 | Volume 12 Issue 27 |

Designfax weekly eMagazine

Archives

Partners

Manufacturing Center

Product Spotlight

Modern Applications News

Metalworking Ideas For

Today's Job Shops

Tooling and Production

Strategies for large

metalworking plants

Wheels:

New piston shape has Volvo Trucks riding wave of increased efficiency

Volvo Trucks' new piston design features six ridges (or waves) in the piston crown that help it burn fuel more efficiently and cut down on soot.

It's been in existence and undergoing continuous development for 140 years, but the internal combustion engine can still be improved. Engineers at Volvo Trucks think one good place to start is with the piston design.

"Over the past years, the focus has mainly been on using computers to more efficiently control the combustion process," says Jan Eismark, technical specialist in combustion systems at Volvo. "It's therefore particularly pleasing that the change we have just made is exclusive to the hardware and the design of the piston crown."

Volvo's clever, new solution is good both for customers and the environment. The more efficient combustion it delivers halves the quantity of soot particles and has reduced fuel consumption by an average of 2 percent.

However, it did require cutting-edge technology to prove that the initial ideas were correct and to identify the exact design of the piston crown. This entailed using computational fluid dynamics (CFD) and high-speed filming of the combustion process inside the cylinder.

When the idea arose to investigate the effects of tweaking the piston shape, the combustion development team at Volvo was attempting to reduce the amount of soot particles in exhaust gases in a project that was partly funded by the Swedish Energy Agency. They were using a single-cylinder engine to test different pistons and fuel injectors. The results of both engine tests and the CFD calculations meant they could see substantial differences in soot quantities between their various designs.

"The design of the combustion chamber seemed to be significant," says Eismark, who started to sketch possible changes to the design.

In a standard piston, the injector is located in the piston top and the fuel is sprayed toward the cylinder sides through a number of orifices in the injector. The combination of heat and pressure causes the fuel to ignite before hitting the wall. The flame hits the wall of the combustion chamber at a speed of up to 50 m/sec, spreads along the piston bowl wall, and then collides with adjacent flames at an angle of 180 degrees -- still at a high speed.

When the flames collide, they compete for the oxygen available there. At the same time, the oxygen in the center of the combustion chamber is never fully utilized.

"Therefore, we wanted to identify a method of leading the flames into the center of the combustion chamber and better utilize the oxygen there," says Eismark.

Ridges (or waves) in the piston crown were the solution. The piston has six such ridges, and the injector, which is located in the center of the piston top, has six orifices to ensure the fuel is sprayed between the ridges. Eismark owns the basic patent for the technology, together with his colleague Michael Balthasar.

Volvo's standard piston design (left) compared to the new "wave-top" version.

But a clever idea will remain only an idea unless it can materialize. The new piston crown must be of at least the same quality as a standard piston crown and it should not cost any more to manufacture.

"Together with our suppliers, we have invested considerable effort into identifying a manufacturing method for the new piston crown," says Frank Löfskog, Volvo's Acting Group Manager at Global Trucks Technology, Powertrain Engineering, the division responsible for heavy-duty engines at the Volvo Group.

Standard pistons are forged and then finished by machining on a precision lathe, but this method will not work with the new design. Instead, the piston must be precision forged to eliminate the need for further processing.

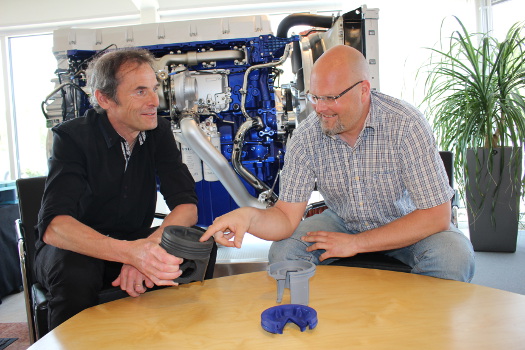

Volvo's Jan Eismark (left) and Frank Löfskog discuss the new piston design for heavy-duty engines.

"The Piston development team, the supplier, and the combustion development team have had many discussions and conducted numerous tests to identify exactly how the piston crown should be designed to deliver the desired advantages and, at the same time, be possible to manufacture in a cost-efficient manner," says Löfskog, emphasizing the cross-functional team effort inside engineering and with purchasing.

But now, the new piston crowns are ready and, in the United States, deliveries of the new engines in trucks from Volvo and Mack will beign January 2017.

Source: Volvo Trucks

Rate this article

View our terms of use and privacy policy